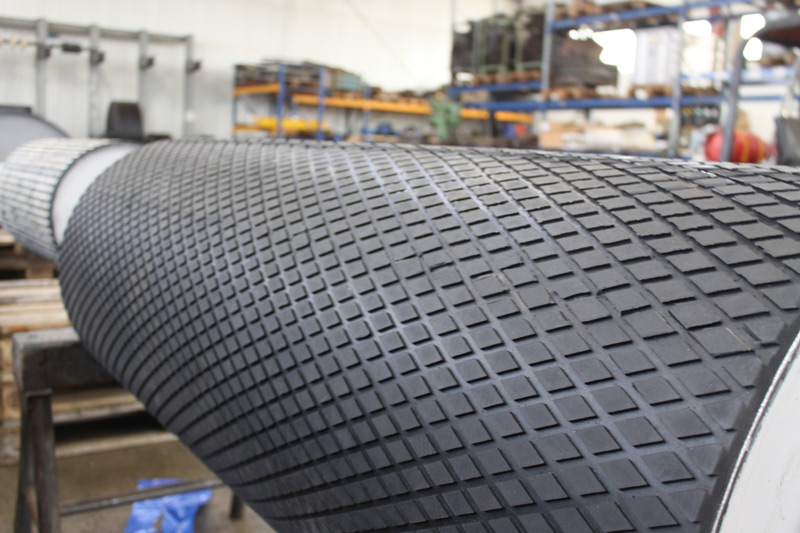

Diamond Grooved Rubber Lagging Sheet

These pulley lagging rubber sheets have diamond grooved design on top surface and another surface is anti skid that eases the installation.

Diamond grooved rubber lagging sheet. These sheets are used in various industries for bulk handling and are resistant to adverse weather temperature and radiation etc. Diamond grooved rubber pulley lagging sheet diamond lagging is often applied in order to extend the life of the shell by providing a replaceable wearing surface or to improve the friction between the belt and the diamond. Skirt rubber lagging sheet. They have a unique blend of natural and synthetic rubber and it prevents conveyor belt slippage.

Diamond pulley lagging rubber sheets are designed to improve the friction coefficient between the drive pulleys and the conveyor belts. They are widely used in various industries for bulk handling and are resistant to adverse weather temperature and radiation. Grooved rubber lagging is generally applied to pulleys which require more fiction to the conveyor belt. Another rubber lagging product is diamond grooved rubber lagging.

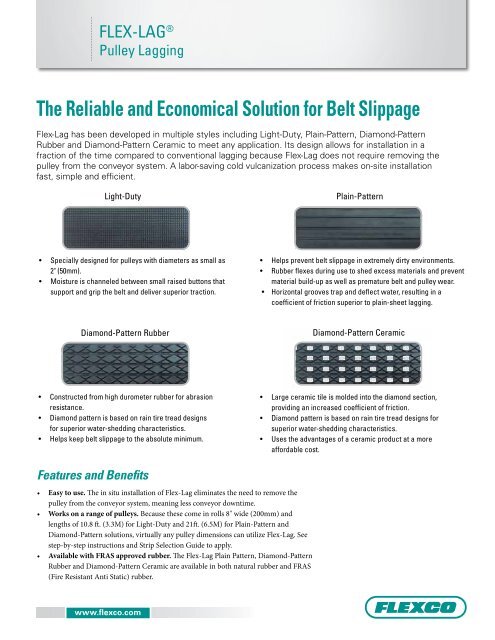

We are manufacturing high performance rubber sheets our sheets are made from exceptionally high wear resistant rubber using a blend of natural synthetic rubber. Conveyor belt materials spillage protection and straight running friction simulation skirt rubber and pulley lagging sheet manufactured of quality natural rubber compound and rubber lagging sheet produced of synthetic rubber neoprene or sbr rubber diamond grooved or plain finish made in india by hic universal. Flex lag rubber lagging has been developed in multiple styles including light duty plain pattern and diamond pattern to meet the needs of any application. Our pulley lagging rubber sheet exhibits some of the best elasticity and are also resistant to any kind of wear and tear.

It also gives excellent resistance to corrosion while reducing any kind of material build up at the same time. Wenco diamond groove pulley lagging is manufactured from high grade natural and synthetic rubber specifically designed to display excellent abrasion and ozone resistance. A number of variations to diamond grooved laggings are available including for example chevron lagging. We use mixture of natural and synthetic rubber for the manufacturing of these pulley lagging rubber sheets.

Our sheets achieve the best abrasion resistant and griping strength. Because the lagging comes in rolls virtually any pulley dimension can utilize flex lag. The diamond grooves are more flexible when compared to plain rubber.