Design Of Sheet Metal Parts Ppt

In low carbon steel sheet metal the minimum radius of a bend should be one half the material thickness or 0 80 mm 0 03 inch whichever is larger.

Design of sheet metal parts ppt. Sheet metal operations not performed on presses 7. It has a significantly lower cost than machining cavities into metal blocks. Modify settings for sheet metal design. Bends in sheet metal are manufactured using sheet metal brakes.

When designing parts for laser cutting one should not make holes smaller than the thickness of the material. Therefore exceptions can be there for complex features design. Design considerations for sheet metal parts. But testing these exceptions before design release is a good practice.

Start the autodesk inventor sheet metal environment. After completing this chapter you will be able to perform the following. Create sheet metal parts. Chapter 10 sheet metal design 1 chapter 10 sheet metal design 2 chapter 10 objectives.

Ppt on sheet metal process 1. In this blog we are going to focus on sheet metal design considerations such as material selection wall thickness bend radii bend allowance. Designers and engineers develop components as small as washers and as large as entire roofs. Products leveraging the possibilities of sheet metal.

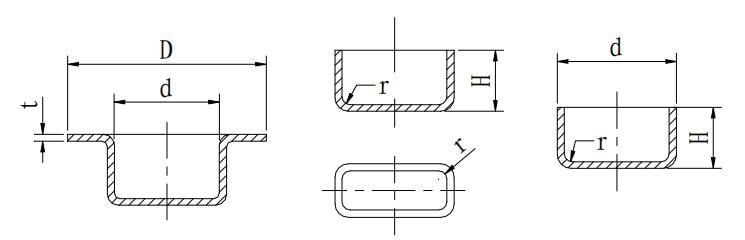

Related to this because the raw materials are single sheets of metal the entire part must have the same material thickness throughout. Sheet metal is one of the most versatile materials and processes in the world today. In this article we will discuss sheet metal design guidelines for manufacturing parts using sheet metal press bending. A 1 degree tolerance on all bend angles.

Sheet metal is one of the most versatile and widely used manufacturing methods. Following all sheet metal design guidelines is very difficult in the complex part. It appears in commodity products and in highly specialized one of a kind applications. Sheet metal parts with a minimum of 0 9mm to 20mm in thickness can be manufactured.

Other sheet metal forming operations 5. Dies and presses for sheet metal processes 6. Modify sheet metal parts to match design requirements. If you design your sheet metal part as a solid object it s important that you send us a cad file that appears folded but shows where bends should go.

Avoid large sheet metal parts with small bent flanges. Sheet metal fabrication in china sheet metal is a kind of integrated metal cold working technology for metal sheet usually in under 6mm usually the parts plastically deformed by handwork or stamping die to form your desired shape and size and it also can be further formed more complex parts by welding or other metal cold working technology including laser cutting punching bending. M p groover fundamentals of modern manufacturing 3 e sheet metalworking 1.