Dense Pack Cellulose Insulation Problems

Good afternoon i live in buffalo ny and am remodeling my home.

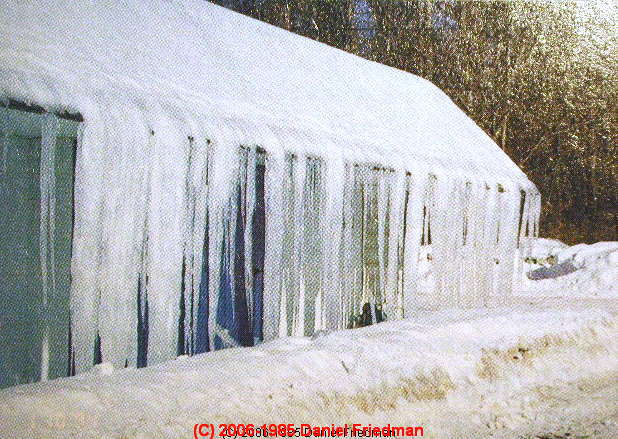

Dense pack cellulose insulation problems. Dense pack cellulose insulation. Cellulose insulation must be kept dry. My energy auditor is telling me to have dense packed cellulose blown into the walls and also add some over the fiberglass batts in the attic. Cellulose insulation problems cellulose settles leaving your home open to air movement.

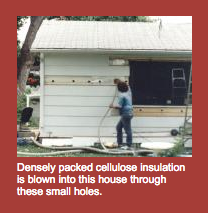

Solving back pressure problems with dense pack cellulose insulation. Admittedly a quality dense pack job is nearly indistinguishable from an inferior one. Dense packed cellulose. This photo from german equipment maker x floc shows the company s dry injection system for cellulose insulation in action.

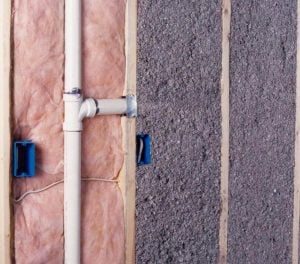

Cellulose fibre insulation cfi is like the rodney dangerfield of insulations it can t get no respect. I would love to insulate the walls but don t want to create a mold problem. Cellulose insulation can absorb up to 130 percent water by weight. The back pressure relief valve allows air to escape so that insulation can be uniformly delivered and compacted while the red filter bag contains dust.

Unfortunately most insulation contracts are decided based on price rather than who does the best job. The difference is how tightly the cellulose is packed into the cavities and you often can t tell just by looking at it. Me thods and verification of density machine settings the air to material ratio is very important. For most machines about 8 000 watts is good.

Me thods and verification of density working out of a pickup inadequate power supply. Higher ratio will increase density. Modern cellulose settles up to 20 percent according to house. 32 dense pack cellulose insulation.

A recent one on cellulose insulation and air vapor barriers one of a flurry on the topic tipped the scale toward a broader response as we continue to dispel this enduring myth. 5 this is unbelievably impressive. The r value of wet spray and dense pack cellulose insulation depends slightly on its installed density and the exact type of cellulose used but commonly ranges between 3 6 and 3 8 per inch 1 as measured by the standard astm c518 test. 0 2 to 1 0 l s m 2 at 75 p.

When we blow them with insulation we dense pack them to around 3 5 lb ft 3 56 kg m 3 density the leakage drops to 0 04 to 0 2 cfm ft 2 at 0 3 in. In an airtight cavity air pressure can hamper the delivery of insulation. Here are some answers. Dense packed cellulose insulation can be a superior product to commonly used batt insulation but somehow it has developed a bad reputation in canada.